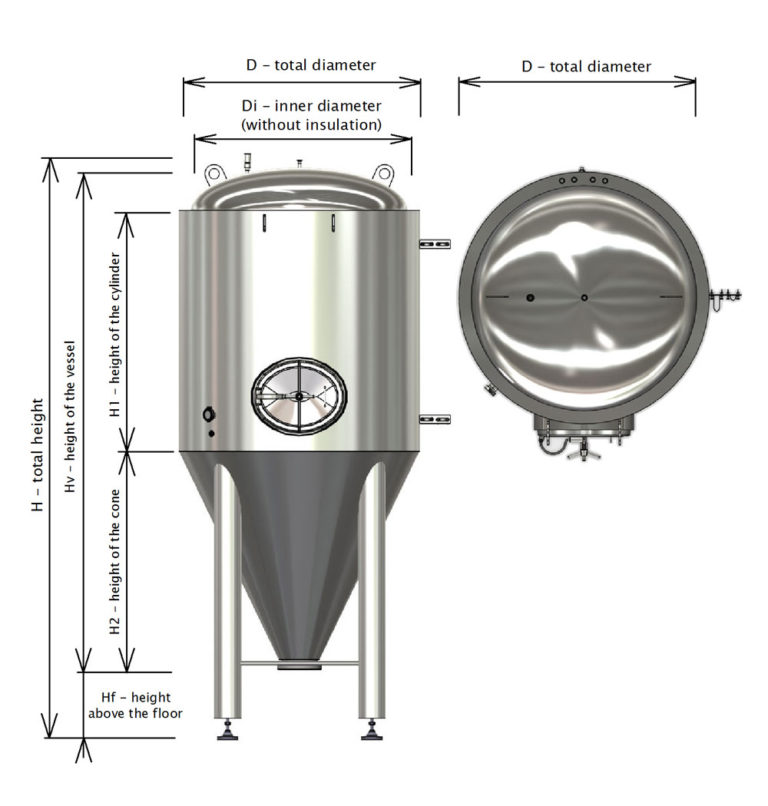

Description of basic tanks of the CCTM modular cylindrical-conical tanks system

CCTM – the modular cylindrically-conical tank – consists of the basic tank (BT) and the modular tank accessories (MTA). Assembling tanks to many desired configurations is possible due to the big number of combinations of expansion accessory that is combined and mounted on the basic tank. It is thus possible to equip the modular tank optimal configuration for the desired part of the beverage production process.

Basic tank

The basic tank is a pressure vessel made of stainless steel AISI 304, according to the standards applicable to food production, with a smooth inner surface (surface roughness 2B / 2J is chosen by the customer). The basic tank consists of a cylindrical body, conical bottom, arched top bottom, 3-4 feet and of armatures for connection of optional accessories. We produce them in versions:

Depending on maximum permissible overpressure:

- Non-pressure tank – maximum achievable overpressure 0.5 bar – suitable only for the main fermentation process (beer, cider, wine) and for production of low-pressure beverages (must, wine)

- Pressure tank – maximum available pressure of 3.0 bar – suitable for main fermentation of all carbonizated alcoholic beverages like beer or cider, fermentation and maturation under pressure, carbonization, flotation, finishing and isobaric bottling of beverages into sale packages like glass bottles, PET bottles, steel kegs.

Depending on the quality and surface finishing:

- SQ – standard quality – SB Ra<0.8μm : grinded inner surface of the cylindrical part, SJ Ra<0.5μm : polished inner surface of the conical part. External steel jacketes with all riveted connections and grinded surface.

- HQ – high quality – SJ Ra<0.5μm : polished all internal surfaces, polished welds. External steel jacketes with all welded connections and grinded surface.

- TQ- top quality – SJ Ra<0.5μm : polished all internal surfaces, polished welds. External steel jacketes with all welded connections and polished surface.

According to the insulation and outer jacket:

- Non-insulated tank – equipped with a double jacket with cooling channels, without PUR insulation, without outer jacket (tha tank has to be place it in insulated room chilled by air)

- Isolated tank – equipped with a double jacket with cooling channels, including PUR insulation, including an external stainless steel jacket (for placing in any room)

Basic tank – description of standard equipment of the tank :

The standard equipment of the basic tank includes:

- IM – Inspection manhole – Oval door with a manhole 450×350 mm with an openable arm in the cylindrical part of the tank (CCT-M tanks with volume equal or higher than 500 liters), or in the upper arched bottom (CCT-M tanks with volume lower than 500 liters)

- SV – Safety valve – special valve with a spring for protection of the tank from overpressure (0.5 bar or 3.0 bar) and underpressure (0.2 bar)

- CP – Sanitizing port – TriClamp connector for connection of the CS1 upper sanitation pipe outside the tank and of the SB1 sanitizing shower inside the tank.

- AL – Adjustable legs – 3 legs for tanks with a capacity up to 3000 liters or 4 legs for larger tanks, with adjustable screwed rubber feet for exact positioning and leveling of the tank

- BT – Bottom throat – lower throat connector (TriClamp or dairy coupling DN125 – DN200 with accordance to the volume of the tank) for connecting of the TO1 universal screwable bottom with welded pipes to filling and draining the tank

- CT – Cooling throats – threated pipes (G 1/2″ – G 2″ with accordance to the volume of the tank) for connecting cooling system (with ice water or glycol solution)

- CC – Cooling channels – cooling channels welded around the cylindrical part (all tanks) and conical part (tanks with volume higher than 500 liters) for intensive circulation of cooling liquid for cooling of tanks or also for heating of the tanks.

- TS – Thermometer sockets – welded pipe sockets DN8 for easy installation of sensors for measuring the temperature and for regulation of the temperature in the tanks.

- HE – Handling hinges (eyes) – crane hinges for manipulation with the tank with help of lifting machines

- LC – Ladder consoles – ladder hinges for easy entry to the upper part of the tank using the stainless steel ladder LAD

- FC – Fill level indicator consoles – welded hinges for safety fixing of the CS2 side sanitation pipe and of the fill level indicator LIS with threaded clamps

- SV – Connector for the sample valve – TriClamp DN10 connector for connecting the SV1 sample valve

- MT – Multifunction throat – TriClamp connector (with accordance to the volume of the tank DN25 – DN60) for connection of additional armatures like the oxigenation-carbonization candle CC1 , the HopGun or of the flotation machine for purification of fruit must in the tank.

Our production portfolio – Basic tanks of the CCT-M system :

[simple-rss feed=”https://eshop.czechminibreweries.com/product-category/bpt/cct-ccf/cctm/cmbt/feed/?post_type=product” limit=”15″ show_date=”0″ hide_description=”0″ show_images=”1″ hide_url=”0″ amount_of_words=”40″]