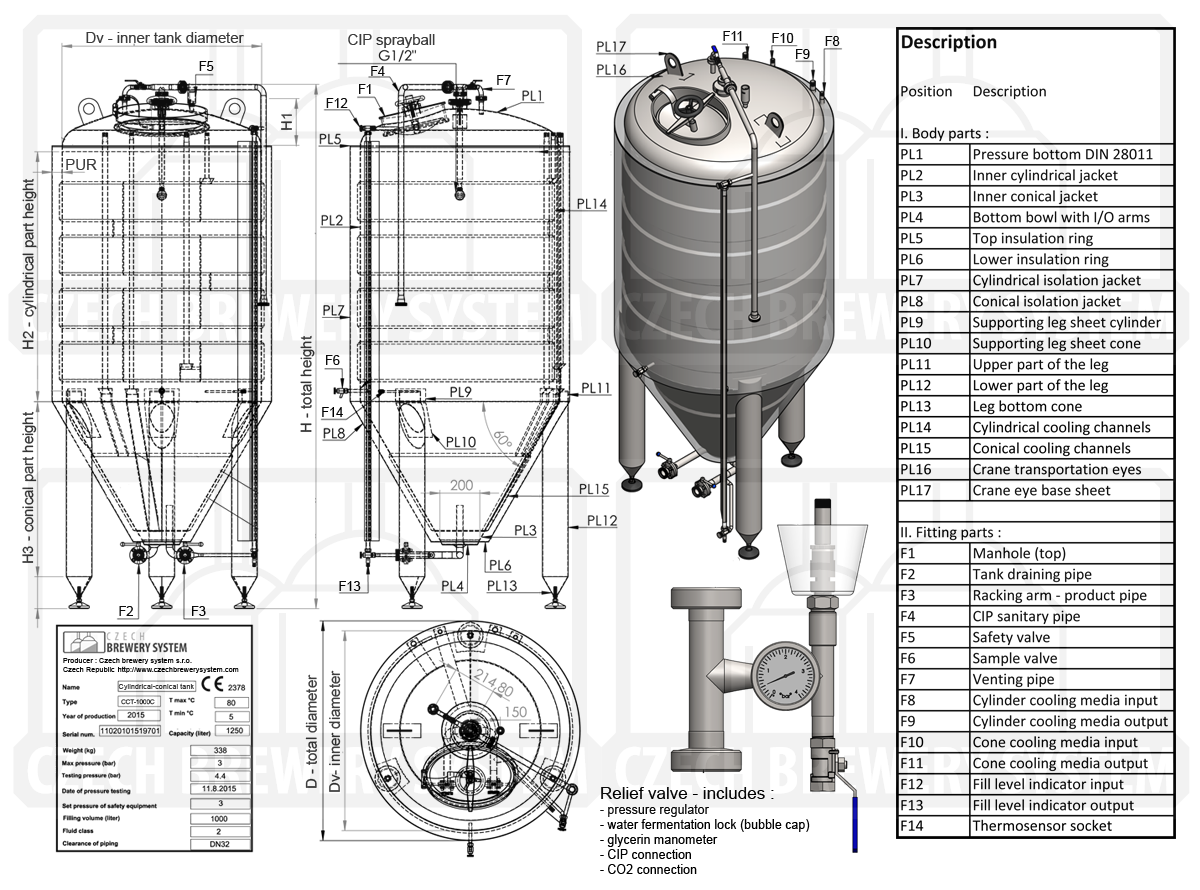

CCT-C Cylindrically-conical fermentation tanks, cooled by liquid, insulated, with Classic design, maximal pressure 3.0bar

CCT-C the classical isolated liquid-cooled cylindrical-conical tanks are a professional solution for all breweries for which cost savings are at the forefront. The tanks are equipped with duplicate cooling channels through which the coolant flows through water or glycol, and are additionally insulated with PUR foam. The outer jacket covers the insulation and forms a clean stainless steel tank design. Tanks can be placed in a non-insulated room, because the insulation ensures their protection against unwanted cold leakage to the surroundings of the tank. Their advantage is above all the low power consumption of tank cooling, the need for a less efficient water cooler, but also the comfort of human service that may not work in a cold environment.

Variations of CCT-C cylindroconical tanks according to their quality and equipment:

According to requirements and financial possibilities of customers we can produce fermentation tanks at three classes of quality:

According to requirements and financial possibilities of customers we can produce fermentation tanks at three classes of quality:

- HQ – HIGH Quality – High quality workmanship of all parts, welded joints and surfaces. The inner surface has a guaranteed roughness Ra μm – glossy design. The outer surface is unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe. A perfect separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same tank. Luxury equipment of the tanks. The main advantages are the savings of sanitizing solutions, water and energy, minimized losses of beverages, shorter work time, reduction of production costs. Three years warranty for stainless steel main parts and also for the fittings. The quality class for the most demanding customers.

- SQ – STANDARD Quality – Standard quality workmanship of all parts, welded joints and surfaces. All functional armatures and fittings that have an impact on the reliability and safety of the products are purchased from approved suppliers from Europe. Inspection of all critical welds and joints. The inner surface has a guaranteed roughness Ra=0.8 μm – semi glossy design. Usual equipment af the vessels, usual set of fittings. Tanks in this quality class comply with all European regulations for pressure vessels and food processing plants. Two years warranty for stainless steel main parts, two year for the fittings. It is the most often ordered quality variaton of tanks for our customers.

- LQ – LOWER Quality – Lower quality workmanship of all parts, welded joints and surfaces. The most of functional armatures and fittings are purchased from approved suppliers from Asia. The inner and outer surface are not unified. Not guaranteed surface roughness on the inside of the containers. One year warranty for stainless steel main parts, one year for the fittings. This solution is interesting only for starting small breweries because it saves an investition costs. Unfortunatelly, this brings higer beverage production costs. Longer period of sanitation, greater consumption of the sanitizing solution, energy, labor and hot water. High losses of produced beverages. We don´t offer this quality class for our products, because the equipment with the LQ quality class does not comply with the European regulations for pressure vessels and food processing plants. It is the quality of tanks of very cheap world producers of the tanks.

CCT - Cylindrical-conical fermentation tanks : Quality + Equipment

| Specification and equipment | HQ | SQ | LQ |

|---|---|---|---|

| Production of the Czech Mini Breweries | optional | standard | we don´t offer |

| Competitors’ production (usual reality) | rarely | optional | standard |

| Main fittings producers | Europe | Europe | Asia |

| *** Inner surface – roughness | Ra < 0.8μm | Ra = 0.8μm | Ra > 0.8μm |

| *** Inner surface – sheen | glossy | semi glossy | matte |

| Outer surface – united design | yes | no | no |

| Connections of outer plates | welved | welved | riveted |

| PU insulation | > 50 mm | > 40 mm | < 40 mm |

| Thickness of the inner plates | > 3 mm | > 3 mm | < 3 mm |

| Thickness of the outer plates | > 1,5 mm | > 1,5 mm | < 1,5 mm |

| * Penetration test | yes | yes | no |

| Design quality | 100% | 100% | unspecified |

| Function quality | 100% | 100% | unspecified |

| * Pressure relief valve – adjustable range | 0 – 3 bar | 0 – 3 bar | 0 – 2 bar |

| * Pressure relief valve – with adjusting scale | yes | extra charge | no |

| Level indicator – sanitable | yes | yes | no |

| Level indicator – with scale | yes | extra charge | no |

| Vacuum-overpressure aeration valve | yes | yes | yes |

| ** Independent safe overpressure valve | 3.3 bar | 3.3 bar | no |

| Rotary shower – pressurizing nozzle | yes | yes | extra charge |

| Racking valve above yeast | yes | yes | yes |

| Racking valve with adjustable suction height | yes | extra charge | no |

| Racking valve with sigh glass | yes | extra charge | no |

| Yeast draining valve | yes | yes | yes |

| Sampling valve – removable | yes | yes | no |

| * Overpressure manhole (upper or side) | yes | yes | yes |

| Cooling area of duplicators | > 60% | > 60% | < 60% |

| * Manometer | yes | yes | yes |

| Thermocouple for each cooling zone | yes | yes | yes |

| * PED 97/23/EC certificate | yes – always | yes – always | rarely |

| * ASME / GUM / GOST-R certificate | optionally | optionally | rarely |

| Warranty | 36 months | 24 months | 12 months |

CCT - Cylindrical-conical fermentation tanks : Quality + Equipment

Asterisks: *= only for ovepressure tanks **= only for volumes more than 1000L ***= only for volumes more than 300L

Our production portfolio – CCT-C cylindroconical fermentation tanks classic insulated 3.0 bar :

- CCT-30000C : Cylindroconical fermentation tank CLASSIC, 0.5-3.0 bar, insulated, 3.0 bar

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 30000 liters and total volume 33000 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European… Read more »

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 30000 liters and total volume 33000 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European… Read more » - CCT-SHP3-1000DE : Cylindrically-conical universal fermentor 1000/1200 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-1000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 1000 liters and total volume 1200 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-1000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 1000 liters and total volume 1200 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-1500DE : Cylindrically-conical universal fermentor 1500/1800 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-1500DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 1500 liters and total volume 1800 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-1500DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 1500 liters and total volume 1800 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-2000DE : Cylindrically-conical universal fermentor 2000/2400 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-2000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 2000 liters and total volume 2400 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-2000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 2000 liters and total volume 2400 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-3000DE : Cylindrically-conical universal fermentor 3000/3300 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-3000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 3000 liters and total volume 3300 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-3000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 3000 liters and total volume 3300 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-4000DE : Cylindrically-conical universal fermentor 4000/5500 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-4000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 4000 liters and total volume 5500 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-4000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 4000 liters and total volume 5500 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-5000DE : Cylindrically-conical universal fermentor 5000/6500 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-5000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 5000 liters and total volume 6500 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-5000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 5000 liters and total volume 6500 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CCT-SHP3-6000DE : Cylindrically-conical universal fermentor 6000/7200 liters 3.0 bar (non-insulated / insulated)

CCT-SHP3-6000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 6000 liters and total volume 7200 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CCT-SHP3-6000DE is a professional universal high-pressure cylindrically-conical fermentation tank with usable volume 6000 liters and total volume 7200 liters for fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - PED-C : PED 2014/68/EU – the European certificate for the pressure equipment

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more » - CCT-6000C-SP3 : Cylindroconical fermentation tank CLASSIC, 3.0 bar, insulated, 6000/7135L (special price – only 3pcs)

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 6000 liters and total volume 7135 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European… Read more »

Cylindrically-conical fermentation tank (CCT, CCF, cylindroconical fermenter) with the usable tank volume 6000 liters and total volume 7135 liters, for fermentation and maturation of beer, cider, wine and other beverages, in several variations, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured containing standardized dimensions and equipment, or according to individual customer requirements. The tank is normally available in several versions (optional dimensions, quality class, maximum pressure). Classic design, PUR insulation, double stainless steel jacket, water (or glycol) cooling duplicators. The tanks designed for maximal pressure higher than 0.5 bar are manufactured in accordance with European… Read more »