All types of the beer production tanks for breweries – descriptions and use

We are a Czech producer of all types beer production tanks

We are a traditional Czech producer of stainless steel fermenters for production beer. We produce also fermentation tanks for the production other similar isobaric beverages. We offer mainly tanks for production of beer, storage of beer, isobaric bottling into kegs or bottles and for other handling with beer. All tanks are produces of food stainless steel (AISI-304 or AISI-316 according use parameters).

We are a traditional Czech producer of stainless steel fermenters for production beer. We produce also fermentation tanks for the production other similar isobaric beverages. We offer mainly tanks for production of beer, storage of beer, isobaric bottling into kegs or bottles and for other handling with beer. All tanks are produces of food stainless steel (AISI-304 or AISI-316 according use parameters).

All pressure vessels are produced in accordance with the strict European standards and guidelines for pressure vessels (EU Directive PED 97/23 / EC Pressure Equipment). We can produce the beer production tanks alternatively in accordance with standards of other countries (GHOST, GUM, TÜV etc.)

Beer production tanks for breweries – equipment and accessories

Beer production tanks are produced in standard or customized design. Our beer production tanks are equipped with standard equipment (it is always described in our offer) according to use, or we can equip them with another additional accessories like special armatures to production of cider or special armatures usable to production of special beer types according to unique recipes.

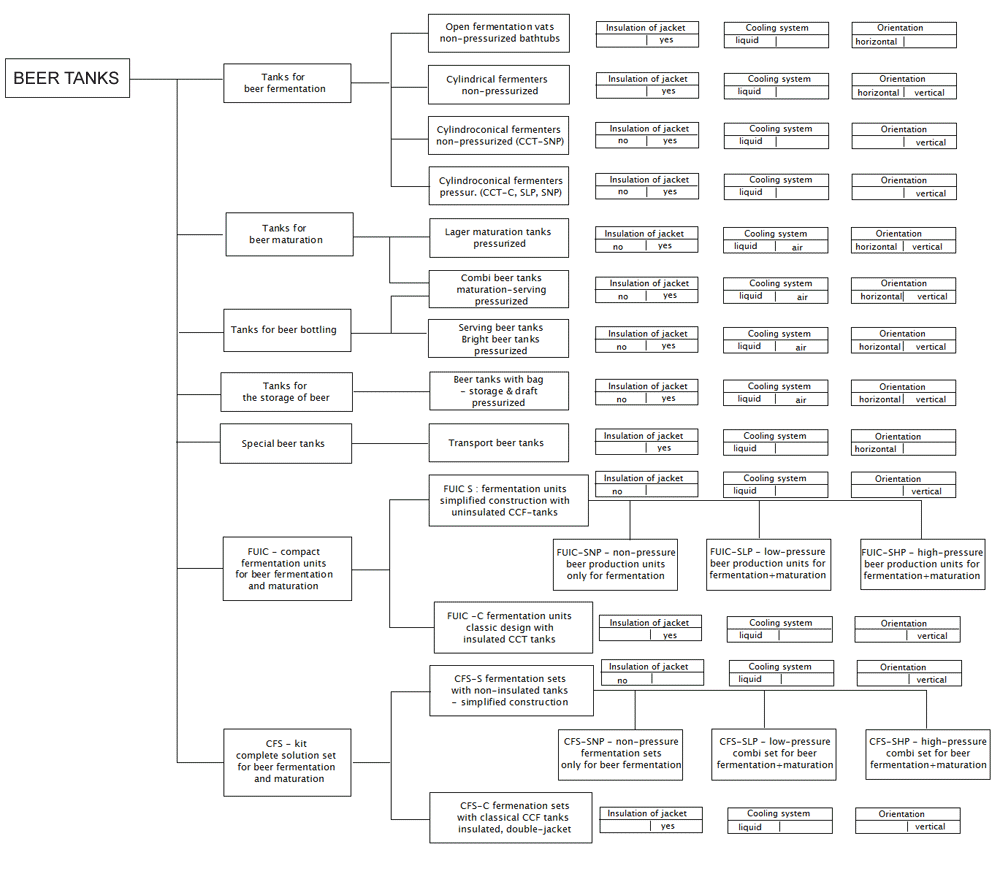

Navigation scheme of brewery tanks of our production :

Beer production tanks

| Product | Description | Design | Insulation | Cooling system | Max. pressure | Info |

| Tanks for the primary beer fermentation process | ||||||

| OFV | Opened fermentation vats - uncovered beer fermentation vessels in the shape of the tub are among the traditional beer production technology, especially of the pilsner type. The advantage is the possibility of collecting "blanket" of dead yeast on the surface of beer. |  | PUR foam > 40mm | Cooling by water or glycol | 0.0 bar | more info |

| CFT | Cylindrical fermentation tanks - Stainless steel non-pressure cylindrical containers for the main fermentation of beer, pressure. They are fitted with an inspection door, sanitizing shower and optional sight glass for monitoring of the fermentation process. |  | PUR foam > 40mm | Cooling by water or glycol | 0.0 bar | more info |

| CCT-SNP | Cylindrically-conical simplified non-pressure fermentation tanks - Stainless steel containers of cylindrical shape with a conical bottom for the main fermentation of beer, non-pressurized. They are equipped with an inspection door, sanitizing shower and armatures for discharge of yeast and beer. Easy separation of yeast from beer. |  | Default = without isolation, but an isolation with the special self-adhesive tank foam is possible. | Cooling by water or glycol | 0.0 bar | more info |

| Tanks for the secondary beer fermentation process - beer maturation | ||||||

| MLT | Maturation tanks - Cylindrical containers which are designed for the second stage of beer fermentation - maturation. Those tanks are equipped with an inspection door, sanitary shower, adjustable pressure valve and fittings for filling and draining beer. We produce them on demand as a versatile tanks that combine function both fermentation and maturation tanks and also pressure bottling tanks - the combi tanks. |  | Non-insulated tanks cooled by air or insulated tanks cooled by glycol. | Cooling by air or by water with glycol | LP version 0-1.5 bar / HP version of 0-3 bar. | more info |

| Tanks for both primary and secondary beer fermentation processes - combi beer tanks | ||||||

| CCT-C/SLP/SHP | Cylindrically-conical pressure tanks - Stainless steel containers with cylindrical body and conical bottom designed for both fermentation and maturation. They are equipped with adjustable pressure valve, an inspection door, sanitary shower and armatures for discharge yeast and beer. Easy separation of yeast from beer. |  | CCF tanks with or without isolation. | Cooling by water or glycol | SLP/SHP version 0-1.5bar / CLASSIC version 0-3bar. | more info |

| PVF | Plastic fermentation vessels - Very simple vessels that allow you production of beer, cider or wine without expensive professional equipment. The current configuration of the plastic fermenters can be simply expanded or changed by a customer using many optional equipment. |  | Optional simple insulation jacket | Cooling with air or water | Pressure of 0.5bar-2.4bar. | more info |

| Tanks for the preparation of the finished beer for its filling into the bottles or kegs | ||||||

| BBT | Cylindrical beer tanks - Stainless steel cylindrical containers with adjustable pressure, dedicated only for temporary storage of beer and preparation beer for filling into bottles or kegs. They are equipped with an inspection door, sanitizing shower, adjustable pressure valve, vacuum valves and armatures for filling and draining of beer. We produce them on demand also as universal tanks , which combines two functions : beer maturation tanks and tanks for bottling beer. |  | Non-insulated tanks cooled by air or insulated tanks cooled by glycol. | Cooling by air or by water with glycol | 3.0 bar | more info |

| Tanks for the storage of beer and serving of beer | ||||||

| DBT | Serving tanks / Draught beer tanks - Tanks for the storage of the finished beer in restaurants and for ease serving of beer into glasses using a conventional air compressor. To avoid contacting beer with air in the tanks are equipped with removable plastic bags, so there is not necessary to use any special inert gases. |  | Non-insulated tanks cooled by air or insulated tanks cooled by glycol. | Cooling by air or by water with glycol | 1.5 - 3.0 bar | more info |

| Special sets and devices with tanks for beer production | ||||||

| FUIC | FUIC - is the compact fermentation and maturation unit which is fully equipped for beer (or cider, wine) fermentation and maturation process, including the independent cooler and temperature measuring and control system. The FUIC is also available for preparation and testing samples of new beer types in breweries. An expanding of the brewery for more fermenters takes only several minutes and whole fermentation and maturation system is immediatelly available. |  | CCF tanks SLP/SHP without isolation (optionally with adhesive insulating foam), CCF tanks CLASSIC are insulated with PUR. | Cooling by water or glycol | SLP/SHP version 0-1.5bar / CLASSIC version 0-3bar. | more info |

| CFS | Complete Fermentation System - The CFS is a complete set of equipment which is needed for the beer (or cider, wine) fermentation and maturation process. Each fermentation set includes one or more cylindrical-conical fermenters, compact glycol cooler, glycol pump and full temperature measuring and control system. CCF fermenters are equipped with cooling duplicators and full fitting set for the professional beer or cider production process. |  | CCF tanks SLP/SHP without isolation (optionally with adhesive insulating foam), CCF tanks CLASSIC are insulated with PUR. | Cooling by water or glycol | SLP/SHP version 0-1.5bar / CLASSIC version 0-3bar. | more info |

Main categories of the beer production tanks :

- Primary beer fermentation tanks – Fermentors and tanks intended to the primary fermentation of beer (non-pressure fermentors)

- Secondary beer fermentation tanks – Fermentors and tanks intended to the secondary fermentation of beer (pressure fermentors)

- Tanks for the final beer conditioning – Pressure tanks for the final beer conditioning / Bright beer tanks / Beer storage tanks

- Yeast regeneration tanks – Tanks and equipment to storage, regeneration, propagation, collection and dosing of brewer´s yeast