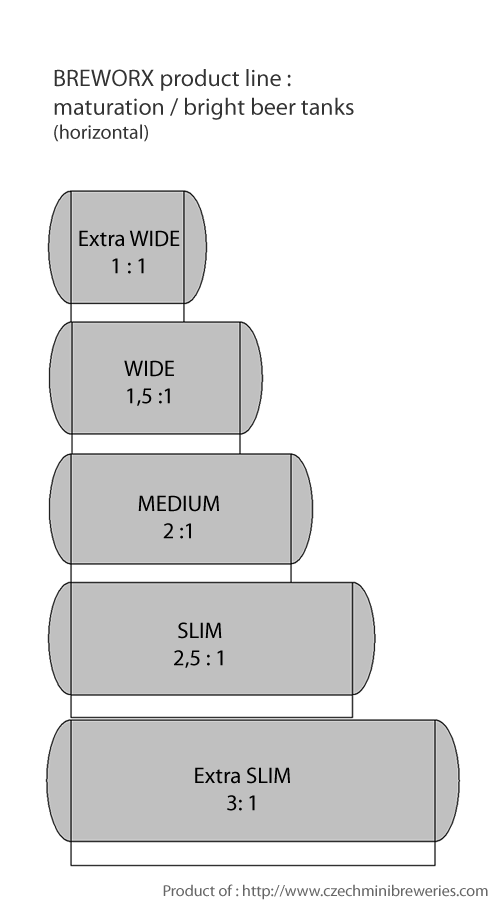

Beer production tanks for the secondary fermentation, with horizontal orientation

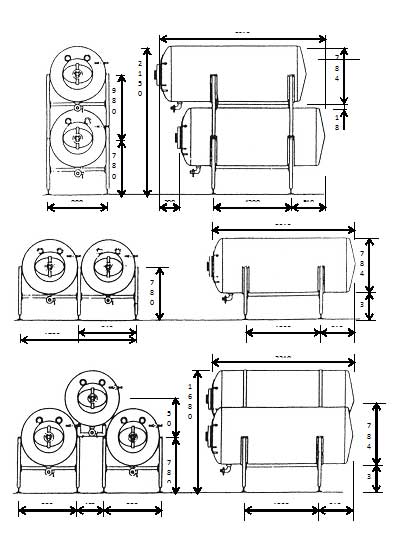

The horizontal orientation of the tanks is practical in breweries with insufficient height for the location of vertical cylindrical beer maturation tanks.

Horizontal cylindrical beer maturation tanks can be positioned in several layers to maximize their number according to the available room height. The main disadvantage of horizontally oriented tanks is, in particular, poor access to hidden space between of the tanks, where is accumulated dirt, which may be the source of unwanted infections of yeast and beer. We recommend the horizontal tanks only for breweries with a really low ceiling height in the beer cellar room.

What is the beer maturation tank intended for ?

The main function of the pressure beer maturation tank is to provide a secondary phase of the beer fermentation – the maturation of beer, which is the natural saturation of the beer by the carbon dioxide which is spontaneously produced during the physical activity of the beer yeasts, at low temperature (usually from 1°C to 4°C) and low pressure (usually from 1.0bar to 2.5bar).

We offer two variations of this type beer tank :

I. MBTHI – Pressure beer maturation tanks, horizontal, insulated

The fully insulated cylindrical beer maturation tanks cooled with liquid are a professional solution for all restaurants keepers for whom the savings of operating costs are at the very first place. Tanks include cooling channels with the flowing cooling liquid. The tanks have a cylindrical part insulated with PUR foam. Also both bottoms of the tank can be insulated for extra surcharge. The outer jacket is covered with insulation and it creates a clean design of stainless steel tank. It is possible to place the tanks in a non-insulated room because insulation provides the protection against unwanted escape of cold from beer tanks. Their advantage is mainly their low electric consumption when the tanks are cooled, the need of the less powerful liquid cooler and high comfort for operators because people may not work in air-cooled space.

Our production portfolio – MBTHI – Pressure beer maturation tanks, horizontal, insulated

- MBTHI-1500C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 1500/1635 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 1500 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 1500 liters, total volume 1635 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 1500 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 1500 liters, total volume 1635 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-2000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 2000/2180 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 2000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 2000 liters, total volume 2180 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 2000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 2000 liters, total volume 2180 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-2500C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 2500/2725 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 2500 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 2500 liters, total volume 2725 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 2500 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 2500 liters, total volume 2725 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-3000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 3000/3270 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 3000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 3000 liters, total volume 3270 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 3000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 3000 liters, total volume 3270 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-4000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 4000/4360 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 4000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 4000 liters, total volume 4360 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 4000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 4000 liters, total volume 4360 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-5000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 5000/5450 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 5000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 5000 liters, total volume 5450 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 5000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 5000 liters, total volume 5450 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-6000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 6000/6540 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 6000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 6000 liters, total volume 6540 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 6000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 6000 liters, total volume 6540 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-7000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 7000/7630 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 7000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 7000 liters, total volume 7630 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 7000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 7000 liters, total volume 7630 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - MBTHI-8000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, insulated, 8000/8720 liters, 0.5/1.5/3.0bar

Universal cylindrical pressure tank with 8000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 8000 liters, total volume 8720 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more »

Universal cylindrical pressure tank with 8000 liters of nominal capacity, with horizontal orientation and PUR insulation, to be cooled with water or polypropylenglycol. According to accessories choosed the pressure tank can be used for the primary fermentation without pressure, secondary fermentation under pressure (maturation) or to final conditioning of alcoholic beverages (carbonization, filtration, pasteurization, flavoring with ingrediences like hops or herbs) before their bottling, filling into kegs or cans. Usable volume 8000 liters, total volume 8720 liters, made of stainless food steel DIN 1.4301 (AISI 304). This tank is equipped with insulation and glycol cooling channels. It is designed for… Read more » - PED-C : PED 2014/68/EU – the European certificate for the pressure equipment

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

… more tanks with other volumes

II. MBTHN – Pressure beer maturation tanks, horizontal, non-insulated

These cylindrical beer maturation tanks have the easiest construction therefore there is possible to purchase them for the lowest price. We produce these tanks in single-jacketed version without any cooling channels. Tanks have to be placed in insulated chilled room or insulated cooling box, where the space is cooled with external air cooling unit. Main advanatage is their low purchase cost. Their disadvantage is that the temperature in each tank cannot be regulated independly regardless of the other tanks. The human operating comfort is lower as well because operators work in cold and humid surroundings. The electric consumption is higher when tanks are cooled with air instead the liquid. Yet this type of tanks is most commonly used in brewery restaurants mainly due to investment savings.

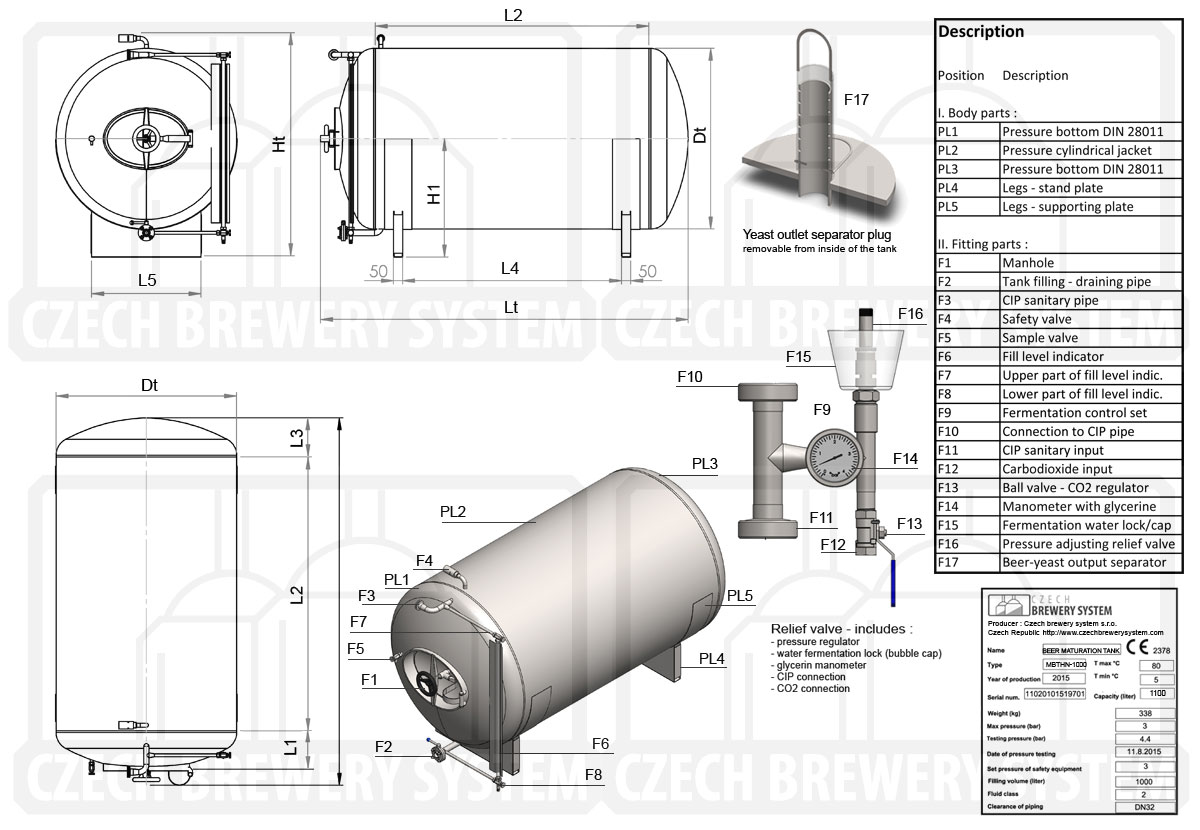

Description of maturation lager beer tank / non-insulated, horizontal, cooled with air :

Our production portfolio – MBTHN – Maturation tanks horizontal, non-insulated

- MBTHN-3000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 3000/3130L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 3000 liters and total volume 3130 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 3000 liters and total volume 3130 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-4000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 4000/4258L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 4000 liters and total volume 4258 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 4000 liters and total volume 4258 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-5000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 5000/5900L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 5000 liters and total volume 5900 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 5000 liters and total volume 5900 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-6000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 6000/6905L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 6000 liters and total volume 6905 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 6000 liters and total volume 6905 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-100C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 100/120L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 100 liters and total volume 120 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 100 liters and total volume 120 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-200C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 200/233L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 200 liters and total volume 233 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 200 liters and total volume 233 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-800C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 800/959L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 800 liters and total volume 959 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 800 liters and total volume 959 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-7000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 7000/7855L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 7000 liters and total volume 7855 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 7000 liters and total volume 7855 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - MBTHN-8000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), horizontal, non-insulated, 8000/8538L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 8000 liters and total volume 8538 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) . This type of the beverage-production tank is equipped with a horizontal stackable construction, it is without insulation therefore it is designed to cooling by air from outside space. This tank has usable volume 8000 liters and total volume 8538 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling… Read more » - PED-C : PED 2014/68/EU – the European certificate for the pressure equipment

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »