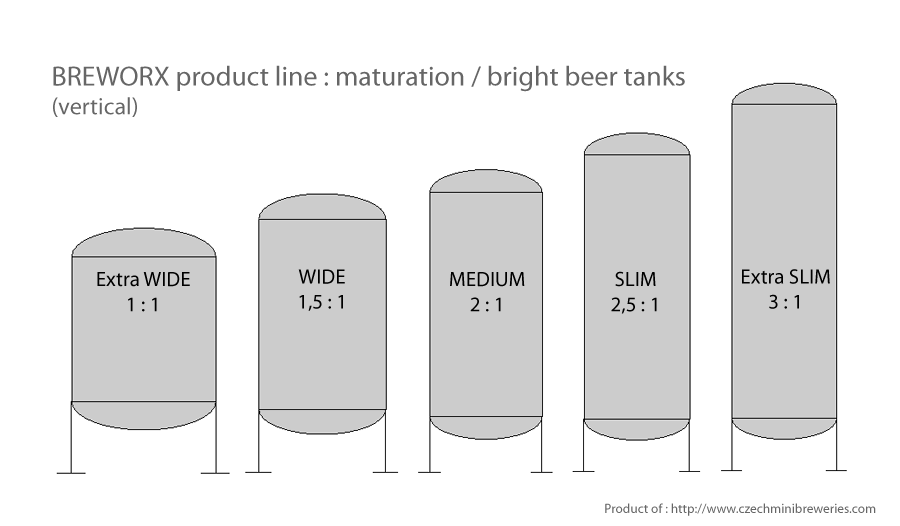

Beer production tanks for the secondary fermentation, with vertical orientation

The vertical orientation of cylindrical beer maturation tanks has many practical advantages:

- Effective cleaning and sanitation of the whole tank with only one rinsing head (cost savings).

- Easy manual cleaning of both inner and outer surface of the tank – usually it is possible to stand in the inside of the tank when cleaning and it is possible to walk around the tank.

- Small space of floor area, effective usage of vertical room space.

- Easy manipulation and access to all armatures and functional parts of the tank.

- Precise tracking of product quantity in a tank using a level gauge.

What is the beer maturation tank intended for ?

The main function of the pressure beer maturation tank is to provide a secondary phase of the beer fermentation – the maturation of beer, which is the natural saturation of the beer by the carbon dioxide which is spontaneously produced during the physical activity of the beer yeasts, at low temperature (usually from 1°C to 4°C) and low pressure (usually from 1.0bar to 2.5bar).

We offer two variations of this type beer tank :

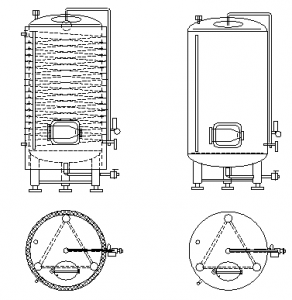

I. MBTVI – Pressure beer maturation tanks, vertical, insulated

The fully insulated cylindrical beer maturation tanks cooled with liquid are a professional solution for all restaurants keepers for whom the savings of operating costs are at the very first place. Tanks include cooling channels with the flowing cooling liquid. The tanks have a cylindrical part insulated with PUR foam. Also both bottoms of the tank can be insulated for extra surcharge. The outer jacket is covered with insulation and it creates a clean design of stainless steel tank. It is possible to place the tanks in a non-insulated room because insulation provides the protection against unwanted escape of cold from beer tanks. Their advantage is mainly their low electric consumption when the tanks are cooled, the need of the less powerful liquid cooler and high comfort for operators because people may not work in air-cooled space.

Our production portfolio – MBTVI – Pressure beer maturation tanks, vertical, insulated

- FMT-SHP-100H : Round-bottom tank, non-insulated, cooled by liquid, 100/120 liters 2.5 bar (simplified fermenter)

FMT-SLP-100H is the simplified high-pressure beverage round-bottom tank with usable volume 100 liters and total volume 120 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SLP-100H is the simplified high-pressure beverage round-bottom tank with usable volume 100 liters and total volume 120 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-200H : Round-bottom tank, non-insulated, cooled by liquid, 200/240 liters 2.5 bar (simplified fermenter)

FMT-SHP-200H is the simplified high-pressure beverage round-bottom tank with usable volume 200 liters and total volume 240 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-200H is the simplified high-pressure beverage round-bottom tank with usable volume 200 liters and total volume 240 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-500H : Round-bottom tank, non-insulated, cooled by liquid, 500/625 liters 2.5 bar (simplified fermenter)

FMT-SHP-500H is the simplified high-pressure beverage round-bottom tank with usable volume 500 liters and total volume 625 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-500H is the simplified high-pressure beverage round-bottom tank with usable volume 500 liters and total volume 625 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-1000H : Round-bottom tank, non-insulated, cooled by liquid, 1000/1150 liters 2.5 bar (simplified fermenter)

FMT-SHP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - MBTVI-20000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), vertical, insulated, 20000/21300L, 0.5/1.5/3.0bar

Universal cylindrical pressure fermentation tank usable as the beverage fermentation tank, beverage maturate tank, bright beer tank, tank for the secondary fermentation under pressure, carbonation tank, tank for other final conditioning of beverages. Nominal volume 20000 liters, total volume 21300 liters. The combi multifunction pressure tank is intended mainly to the secondary fermentation (maturation process) of the alcoholic beverage products, storage, carbonation, filtration of beer, cider, sparkling wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs. The pressure vessel is made of stainless food steel DIN 1.4301 (AISI 304), with… Read more »

Universal cylindrical pressure fermentation tank usable as the beverage fermentation tank, beverage maturate tank, bright beer tank, tank for the secondary fermentation under pressure, carbonation tank, tank for other final conditioning of beverages. Nominal volume 20000 liters, total volume 21300 liters. The combi multifunction pressure tank is intended mainly to the secondary fermentation (maturation process) of the alcoholic beverage products, storage, carbonation, filtration of beer, cider, sparkling wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs. The pressure vessel is made of stainless food steel DIN 1.4301 (AISI 304), with… Read more » - MBTVI-30000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), vertical, insulated, 30000/33100L, 3.0bar

Universal cylindrical pressure fermentation tank usable as the beverage fermentation tank, beverage maturate tank, bright beer tank, tank for the secondary fermentation under pressure, carbonation tank, tank for other final conditioning of beverages. Nominal volume 30000 liters, total volume 33100 liters. The combi multifunction pressure tank is intended mainly to the secondary fermentation (maturation process) of the alcoholic beverage products, storage, carbonation, filtration of beer, cider, sparkling wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs. The pressure vessel is made of stainless food steel DIN 1.4301 (AISI 304), with… Read more »

Universal cylindrical pressure fermentation tank usable as the beverage fermentation tank, beverage maturate tank, bright beer tank, tank for the secondary fermentation under pressure, carbonation tank, tank for other final conditioning of beverages. Nominal volume 30000 liters, total volume 33100 liters. The combi multifunction pressure tank is intended mainly to the secondary fermentation (maturation process) of the alcoholic beverage products, storage, carbonation, filtration of beer, cider, sparkling wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs. The pressure vessel is made of stainless food steel DIN 1.4301 (AISI 304), with… Read more » - CFT-SHP3-1000DE : Cylindrical tank / fermentor 1000/1150 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-1000DE is a professional high-pressure cylindrical fermentation tank with usable volume 1000 liters and total volume 1150 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-1000DE is a professional high-pressure cylindrical fermentation tank with usable volume 1000 liters and total volume 1150 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CFT-SHP3-1500DE : Cylindrical tank / fermentor 1500/1750 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-1500DE is a professional high-pressure cylindrical fermentation tank with usable volume 1500 liters and total volume 1750 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-1500DE is a professional high-pressure cylindrical fermentation tank with usable volume 1500 liters and total volume 1750 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CFT-SHP3-2000DE : Cylindrical tank / fermentor 2000/2400 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-2000DE is a professional high-pressure cylindrical fermentation tank with usable volume 2000 liters and total volume 2400 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-2000DE is a professional high-pressure cylindrical fermentation tank with usable volume 2000 liters and total volume 2400 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - PED-C : PED 2014/68/EU – the European certificate for the pressure equipment

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

… more tanks with other volumes

II. MBTVN – Pressure beer maturation tanks, vertical, non-insulated

These cylindrical beer maturation tanks have the easiest construction therefore there is possible to purchase them for the lowest price. We produce these tanks in single-jacketed version without any cooling channels. Tanks have to be placed in insulated chilled room or insulated cooling box, where the space is cooled with external air cooling unit. Main advanatage is their low purchase cost. Their disadvantage is that the temperature in each tank cannot be regulated independly regardless of the other tanks. The human operating comfort is lower as well because operators work in cold and humid surroundings. The electric consumption is higher when tanks are cooled with air instead the liquid. Yet this type of tanks is most commonly used in brewery restaurants mainly due to investment savings.

Our production portfolio – MBTVN – Maturation tanks vertical, non-insulated

- MBTVN-15000C : Cylindrical pressure tank for the secondary fermentation of beer or cider (maturation, carbonization), vertical, non-insulated, 15000/16667L, 0.5/1.5/3.0bar

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) with a vertical construction, without insulation, cooled by air from outside, with usable volume 15000 liters and total volume 16667 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs in several variants, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured… Read more »

The combi multifunction Maturation lager tank & Bright beer tank (called also Lager tank, Secondary fermentation tank, Beer pressure tank, Lagering tank, Pressure fermenter) with a vertical construction, without insulation, cooled by air from outside, with usable volume 15000 liters and total volume 16667 liters, that is designed to secondary fermentation (maturation process) of the alcoholic beverage products, storage, tapping, carbonation, filtration of beer, cider, wine and other beverages under pressure, and also for preparation of beverages before their bottling or filling into kegs in several variants, made of stainless food steel DIN 1.4301 (AISI 304). The vessel is manufactured… Read more » - FMT-SLP-1000H : Round-bottom tank, non-insulated, cooled by liquid, 1000/1150 liters 1.2 bar (simplified fermenter)

FMT-SLP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 1.2bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SLP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 1.2bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-100H : Round-bottom tank, non-insulated, cooled by liquid, 100/120 liters 2.5 bar (simplified fermenter)

FMT-SLP-100H is the simplified high-pressure beverage round-bottom tank with usable volume 100 liters and total volume 120 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SLP-100H is the simplified high-pressure beverage round-bottom tank with usable volume 100 liters and total volume 120 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-200H : Round-bottom tank, non-insulated, cooled by liquid, 200/240 liters 2.5 bar (simplified fermenter)

FMT-SHP-200H is the simplified high-pressure beverage round-bottom tank with usable volume 200 liters and total volume 240 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-200H is the simplified high-pressure beverage round-bottom tank with usable volume 200 liters and total volume 240 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-500H : Round-bottom tank, non-insulated, cooled by liquid, 500/625 liters 2.5 bar (simplified fermenter)

FMT-SHP-500H is the simplified high-pressure beverage round-bottom tank with usable volume 500 liters and total volume 625 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-500H is the simplified high-pressure beverage round-bottom tank with usable volume 500 liters and total volume 625 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - FMT-SHP-1000H : Round-bottom tank, non-insulated, cooled by liquid, 1000/1150 liters 2.5 bar (simplified fermenter)

FMT-SHP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more »

FMT-SHP-1000H is the simplified low-pressure beverage round-bottom tank with usable volume 1000 liters and total volume 1150 liters for both fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0bar to 2.5bar, non-insulated tank or partitially insulated with a simple insulation jacket (depending on the choosed version) , with water (or glycol) cooling channels. Read more » - CFT-SHP3-1000DE : Cylindrical tank / fermentor 1000/1150 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-1000DE is a professional high-pressure cylindrical fermentation tank with usable volume 1000 liters and total volume 1150 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-1000DE is a professional high-pressure cylindrical fermentation tank with usable volume 1000 liters and total volume 1150 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CFT-SHP3-1500DE : Cylindrical tank / fermentor 1500/1750 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-1500DE is a professional high-pressure cylindrical fermentation tank with usable volume 1500 liters and total volume 1750 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-1500DE is a professional high-pressure cylindrical fermentation tank with usable volume 1500 liters and total volume 1750 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - CFT-SHP3-2000DE : Cylindrical tank / fermentor 2000/2400 liters 3.0 bar (non-insulated / insulated)

CFT-SHP3-2000DE is a professional high-pressure cylindrical fermentation tank with usable volume 2000 liters and total volume 2400 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more »

CFT-SHP3-2000DE is a professional high-pressure cylindrical fermentation tank with usable volume 2000 liters and total volume 2400 liters for storage, fermentation and maturation of beer, cider, wine and other beverages, made of stainless food steel DIN 1.4301 (AISI 304). Adjustable pressure from 0 bar to 3.0 bar, optionally non-insulated or insulated, with water(or glycol) cooling channels. The fermentor is completely designed and made in EU. This offer and price includes the tank which is equipped with all standard equipment. This equipment may be replaced or supplementedand with other accessories described in the section “Optional accesories” Read more » - PED-C : PED 2014/68/EU – the European certificate for the pressure equipment

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »

The PED certificate is a necessary document for every pressure device with a permissible pressure greater than 0.5 bar (0.5 MPa), which is intended for use in European countries and in other countries that use and accept European technical standards. Read more »