Opened fermentation tanks for the non-pressure beer fermentation

Opened fermentation vats, uncovered fermentation tanks, beer fermentation bathtubs, pressureless fermentation vats, open beer fermenters – these are the most common names of the special containers designed for the non-covered primary fermentation of beer before beer is pumped into the maturation tanks (for the secondary beer fermentation process). Wort is pumped from the wort brew machine into the fermentation vat immediately after the hot brewing process. These containers are usually located in a separate room, called “spilka” (usual in the Czech Republic).

Opened fermentation vats, uncovered fermentation tanks, beer fermentation bathtubs, pressureless fermentation vats, open beer fermenters – these are the most common names of the special containers designed for the non-covered primary fermentation of beer before beer is pumped into the maturation tanks (for the secondary beer fermentation process). Wort is pumped from the wort brew machine into the fermentation vat immediately after the hot brewing process. These containers are usually located in a separate room, called “spilka” (usual in the Czech Republic).

The main function of the opened fermenter is to ensure the first fermentation phase (the main fermentation) of wort. During the primary fermentation process, the majority of sugars are converted to alcohol, which is produced by the activity of live beer yeast at a fermentation temperature, according to the type of yeast used from 6°C to 12°C (applies to beer produced by the bottom fermentation method) or from 15°C to 24°C (applies to beer produced by the upper fermentation method).

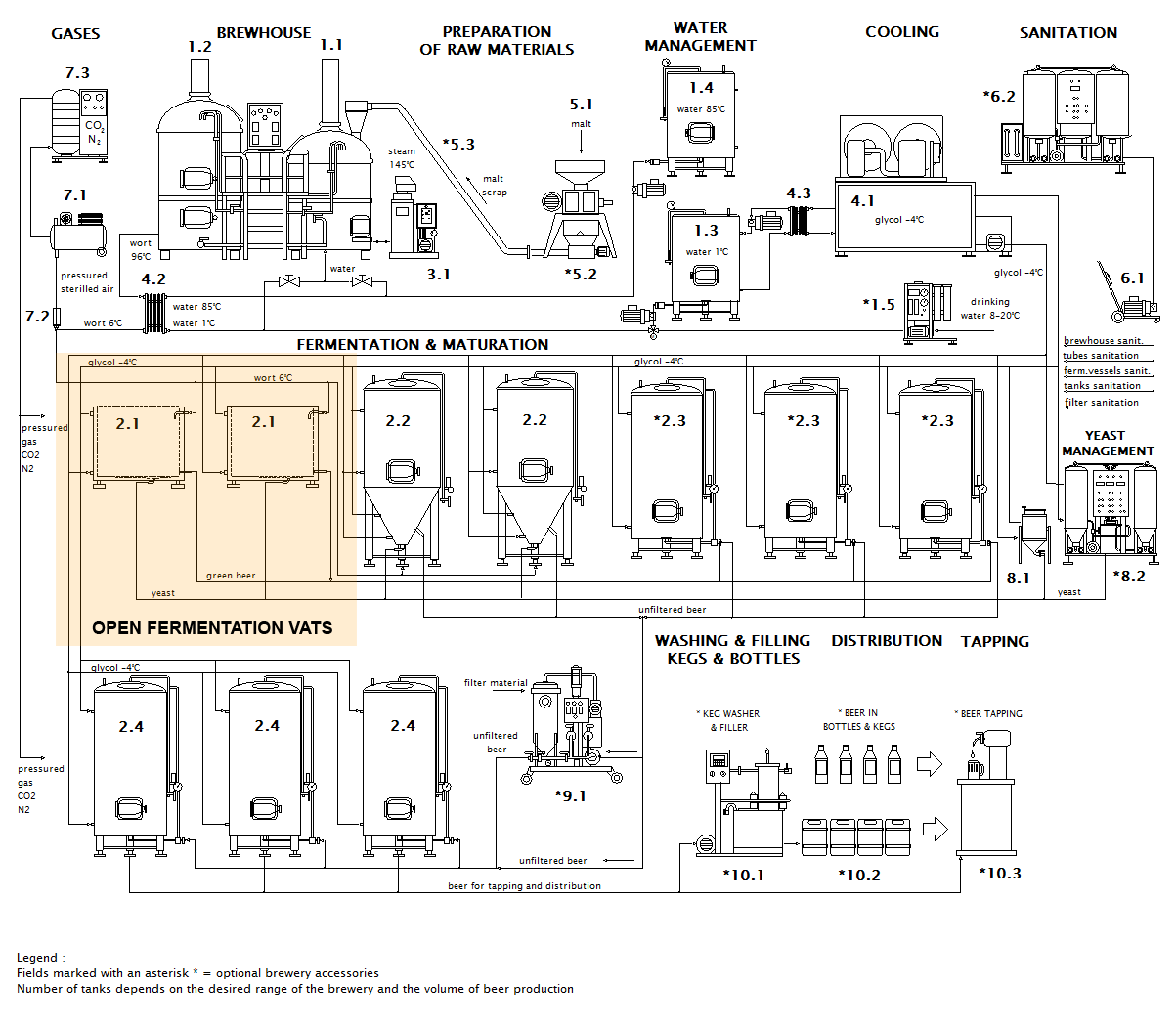

Usual position of the opened fermentation vats in a brewery :

Characteristics of open fermentation containers

Opened fermentation tanks, located usually in separated fermentation room that is dedicated only for the primary fermentation of beer, are a specialty of traditional Czech brewing. Foreign beer manufacturers rarely use these fermenting pots, and if they are, they are usually purchased from Czech manufacturers.

Opened fermentation tanks, located usually in separated fermentation room that is dedicated only for the primary fermentation of beer, are a specialty of traditional Czech brewing. Foreign beer manufacturers rarely use these fermenting pots, and if they are, they are usually purchased from Czech manufacturers.

Fermentation of beer in open fermenters (“open fermentation”) is based on centuries-old traditions of brewing beer not only in the Czech lands. In containers of similar construction (previously not stainless steel but often wood, concrete, ceramic or enamel), beer was produced at the beginning of the historical development of the brewing craft beer. Especially the smallest breweries are traditionally equipped with opened beer-fermentation vessels, to preserve the original recipes and the taste of beer at the same time as most modern breweries have long been using closed stainless steel tanks for main fermentation.

Why opt for an opened fermentation of beer ?

Notwithstanding the respect of tradition, the main advantages of beer production in open fermenting vats include:

- Slower main fermentation of beer, which is not accelerated by increased pressure, and for which the beer has enough time to deeply fermentation, even before being pumped out into beer maturation tanks.

- Possibility of collectioning of bitter foam of loose dead yeasts on the surface of fermented beer. Because of this, the yeast foam does not fall into a young beer and does not contaminate it with a parasitic bitter flavor, typical for making in closed containers (where the foam is not usually collected and therefore the foam is able to fall through beer into the conical bottom of the container, which may to contamine the beer).

- Marketing effect – Unlike brewers that are equipped with closed tanks, the brewery equipped with opened fermenters, has the opportunity to show visitors a beer in the intermediate status, where the room is full of interesting scents and visitors can admire the foam of a variety of colors and structures. Thanks to this, guests get interesting experiences from the brewery’s visit. And they are leaving the brewery with new experience that they felt and saw something more than just a “pile of iron”.

What do you need to prepare for?

The brewery operator who wishes to equip the brewery with opened fermentation tanks must also to know some of the specifics this type fermentation tanks :

- The need for a reserved room for fermentation vessels. Open fermentation vats must be placed in a separate room. This room must be completely sterile, with no air conditioning or other ventilation system (it is only necessary to periodically outgoing the CO2 gas from the floor during fermentation).

- Brewmasters and visitors should visit this room always in pure white coats, and do not touch the fermentation vessels. Entry into the fermentation room must be completely secure against insect infestation, sick people and people suffering from coughing or rhinitis. Particularly in the production of upper fermenting beer, this requirement is an absolutely essential hygienic assumption. This is due to the considerable susceptibility of openly fermenting beer to getting an infection from the air, which leads to spoilage of the beer batch.

- Separation of containers with beer produced by the bottom fermentation method and containers with beer produced by the upper fermentation method. In one and the same room, it is never allowed to produce upper fermented beer together with any beer fermented on bottom. There is always risc of a cross contamination between different yeast species, which results in deterioration or full destructive of the beer batch.

- In the fermentation room with beer produced by the bottom fermentation method it is not possible to store yeast for beer produced by the upper fermentation method and vice versa. For the simultaneous production of both types of beers, it is necessary to operate two separate rooms, not interconnected by, for example, a door or a suction system.

- In the fermentation room is not recommended the machinery cleaning of fermentation vessels. Each fermentation vat must be thoroughly cleaned prior to use from all residues and sediments from the previous batch as well as from dust and other impurities. This must be done mostly by hand using brushes, washing sponges and flowing water, but not use jet-rinsing water in the fermentation vats. If a worker cleans an empty vat in a room where beer is being fermented in one of the adjacent containers, it is excluded to use, for example, a pressure water-cleaner. Also, when cleaning the vat with a brush, care should be taken to avoid contamination of neighboring filled containers with cleaning detergents, dirty water, or yeast residues. Optionally, to facilitate the rinsing of opened fermentation vats, we offer the covering lid with a rotary sanitizing shower as accessories. But still, the thickest sediments of died yeast must be cleaned by brush by hand first, especially of the rests of beer foam level on the walls of the vat.

What happens after the end of the main beer fermentation?

Upon completion of the main fermentation process in open fermentation vats (this takes usually 5-12 days depending on the type of beer), the beer is pumped using the pump into the beer maturation tanks. This is where the stage of the long time maturation of beer, takes place here (typical for lager beer type). During this time the beer maturates for about 2-15 weeks depending on the type of beer, and the beer is saturated with the naturally occurring carbon dioxide (during secondary fermentation) to obtain the resulting form and taste of beer.

The most commonly used type of tanks for the maturation process are the pressure cylindrical tanks and the pressure cylindrically-conical tanks.

Standard equipment of pressureless open fermentation vats :

- Basic non-pressure vessel – the base of the tank is a non-pressure vessel of a rectangular shape or cylindrical shape, consisting of a tub or cylindrical casing and arched bottom .

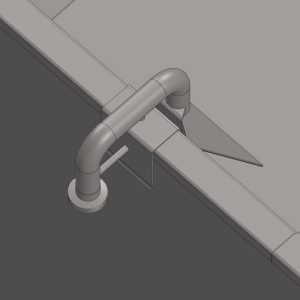

- Filling armature – special removable inlet knee that is attached to the upper edge of the fermentation vat when the wort is filled into a vat.

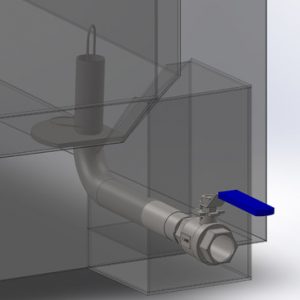

- Outlet with a butterfly valve – a tube with a shut-off valve at the end that serves to discharge the tank contents. For most open fermentation tanks, it also performs the filling function.

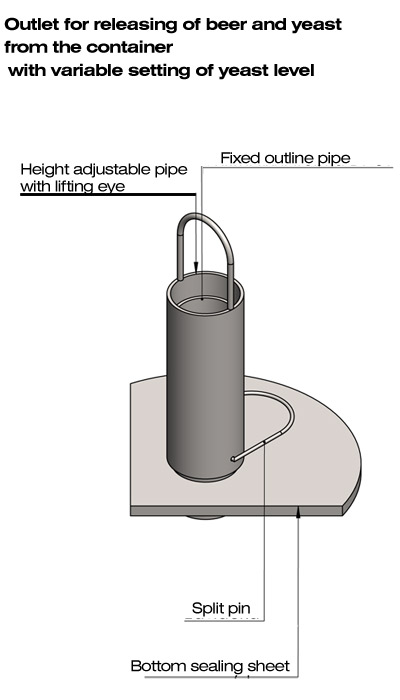

- Outlet adapter for dispense of beer and yeast – the so-called “doll” – serves for easy separation of the product from sedimented yeast. First, the content of the tank is drained above the top edge of the adapter, then the adapter is pulled out with a chain, and the remaining content of the tank with the yeasts is finally fully drained out from the tank. For more expensive tanks, this adapter is replaced by a dedicated drain outlet.

- Temperature sensor in the tube-socket – the tube-socket is welded at the bottom of the tank, the thermosensor of the control system or a thermometer for visual temperature measurement is inserted in the socket.

- Adjustable Feet – The screw feet at the bottom end of the legs are used to accurately nivelation the tank in a vertical or horizontal position (due to the sloping floor because the tank is seldom naturally standing on a horizontal plane)

- Dimple cooling jacket with duplicators – Cooling of the tank is done with liquid in double jacket of the tanks (most commonly using glycol with water), which flows through the double jacket with cooling channels welded on walls of the container and the coolant circulates between the jacket and glycol cooler. Then temperature in the tank is controlled by a control system that compares the measured temperature in the tank with the desired temperature. The automatic control system opens and closes the valves on the inlets into the cooling jacket.

- PUR-foam insulation – The tank is usually insulated with polyurethane foam (optionally with other insulating material) that fills the space between the inner base tank and the outer shell of the tank. Typically, we only isolate the walls of the tank and, on request, we also can insulate a lower bottom of the tank.

Optional equipment of pressureless open fermentation vats :

- Sample Valve – The small cock is used for sampling the product during its tasting and laboratory tests. The valve can be further equipped with a spiral attachment that eliminates the foaming of the beverage and speeds up the sampling process.

- CIP sprayball – a spherical shower for easy washing and sanitation of the tank with water and sanitizing solutions. The shower usually has an effective omni-directional shower head, which may be also rotating (only in more expensive tanks). With open fermentation tanks, the shower is supplied as a detachable part of the optional sanitary cover.

- Transport hinges – Hooks for hanging the tank under the lifting device (crane, forklift) for easy and safe tank transport. We recommend it for tanks with volumes more than 500 liters.

- Temperature Measurement and Control System – in case of a customer’s request, we can supply a complete system for measuring and regulating temperature in tank. We may also deliver the water-glycol cooler. The entire system is easy to install by the customer, no authorized electrician is required for installation and commissioning.

Opened fermentation vats cooled by liquid, with insulation or without insulation

According to customer requirements, we supply open fermentation vats in these variants in terms of cooling and insulation:

1. Opened fermentation tanks cooled by liquid, non-insulated

The most commonly used open fermenting vats are cheaper than the isolated vats, both of which are always liquid-cooled. The tanks contain duplicate cooling channels through which cooling water or glycol flows. The tanks have no insulation and the outer sheath. Tanks should be placed in an isolated room or in an isolated box where there is no excessive heating of the tanks by air.

The most commonly used open fermenting vats are cheaper than the isolated vats, both of which are always liquid-cooled. The tanks contain duplicate cooling channels through which cooling water or glycol flows. The tanks have no insulation and the outer sheath. Tanks should be placed in an isolated room or in an isolated box where there is no excessive heating of the tanks by air.

Their advantage is the relatively low purchase price, the disadvantage is higher energy consumption when cooling tanks, and also the need for a more efficient water cooler than for isolated tanks.

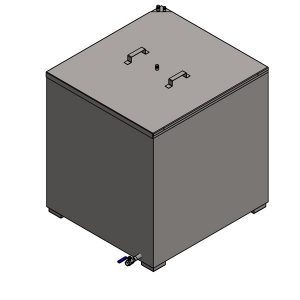

2. Open fermentation tanks cooled by liquid, insulated

Isolated liquid-cooled open fermentation vats are a professional solution for all breweries for which operating costs are the first requirement. Tanks contain duplicate cooling channels through which cooling water or glycol flows. Tanks have walls insulated with PUR foam (for extra charge also insulated bottom) . The outer sheath covers insulation and forms a clean stainless steel tank design. Tanks can be placed in a non-insulated room, because the insulation ensures their protection against unwanted leakage of temperature to the surroundings of the tank.

Isolated liquid-cooled open fermentation vats are a professional solution for all breweries for which operating costs are the first requirement. Tanks contain duplicate cooling channels through which cooling water or glycol flows. Tanks have walls insulated with PUR foam (for extra charge also insulated bottom) . The outer sheath covers insulation and forms a clean stainless steel tank design. Tanks can be placed in a non-insulated room, because the insulation ensures their protection against unwanted leakage of temperature to the surroundings of the tank.

Their advantage is the low electrical power consumption, the need for a less efficient water cooler, but also the comfort for human service that may not work in a cold environment.

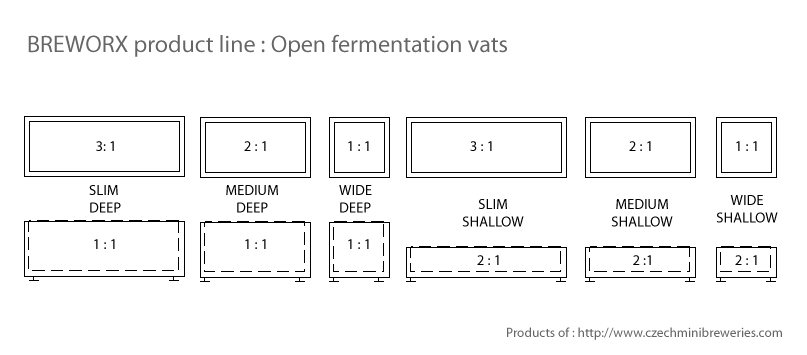

We produce open fermenting vats with variable dimensions

Dimensions of opened fermentation tanks can be customized to customer requirements. The aspect ratio of the tanks can be selected from several variants according to space dispositions of the room.

Our production portfolio – OFV – Opened fermentation vats, insulated

- OFV-2000 Opened fermentation vat 2000 liters

Opened fermentation vat with usable volume 2000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 2000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-2500 Opened fermentation vat 2500 liters

Opened fermentation vat with usable volume 2500 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 2500 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-3000 Opened fermentation vat 3000 liters

Opened fermentation vat with usable volume 3000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 3000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-4000 Opened fermentation vat 4000 liters

Opened fermentation vat with usable volume 4000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 4000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-6000 Opened fermentation vat 6000 liters

Opened fermentation vat with usable volume 6000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 6000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-8000 Opened fermentation vat 8000 liters

Opened fermentation vat with usable volume 8000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 8000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-400 Opened fermentation vat 400 liters

Opened fermentation vat with usable volume 400 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 400 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-5000 Opened fermentation vat 5000 liters

Opened fermentation vat with usable volume 5000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 5000 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-200 Opened fermentation vat 200 liters

Opened fermentation vat with usable volume 200 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 200 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more » - OFV-100 : Opened fermentation vat 100 liters

Opened fermentation vat with usable volume 100 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »

Opened fermentation vat with usable volume 100 liters of beer wort. This is a traditional technology for production of typical Czech lager beer. This fermentor is designed only for the wort primary fermentation process without pressure, not for the secondary fermentation under pressure. The open fermentation vats are recommended mainly for production of beer types which recipe is based on using of the bottom yeasts. Read more »